Abstract: Happy tail

Type and Average of Pigs on the Farm

Sows: 3,700

Weaners: 76,000

Grower-finishers: 42,750

Farming System

Intensive, Large-scale

Description and Evaluation of the Good Practice

The ‘Happy Tail’ approach consists of a set of good practices that eliminate the need for tail docking and teeth clipping. Key elements include:

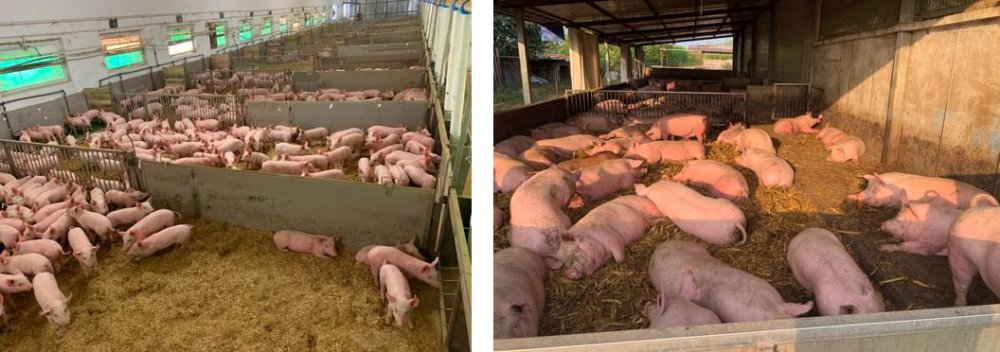

- Straw: Nearly all farms use solid flooring with straw. 100% of farms provide straw from 7 to 30 kg (15,200 places x 5 cycles/year), and about 70% from 30 to 180 kg (16,500 places x 1.8 cycles/year).

- Space: Space allowance per pig is at least 30% above legal minimums: 0.5 m²/head in weaning, 1.3 m²/head in fattening, and 2.6 m²/head for sows.

- Health: 2,700 out of 3,700 sows are PRRS-free, and strict biosecurity measures are in place.

- Environmental control: Sheds are divided into 3 sectors to allow rotation and full straw replacement every 10 days. Temperature, humidity, CO₂, and ammonia are monitored, with corrective actions taken when thresholds (e.g., 10 ppm ammonia) are exceeded.

Farm Context

- Environmental Enrichment

Manipulable materials: Straw is used in all areas with solid flooring. Wood is used in areas with slatted flooring.

Bedding material: Straw is the primary bedding material. - Pigs

Genetic type: Topigs Norsvin

Tail docking: 0% (no tail docking practiced) - Housing and Management Characteristics

Stocking density:

– Weaners: ≥ 0.5 m²/head

– Fatteners: ≥ 1.3 m²/head

– Sows: ≥ 2.6 m²/head

Number of pigs per pen: 30 to 300

Undocked and docked pigs are not mixed.

Flooring: Solid with litter for 16,500 pigs; slatted for 5,500 pigs.

Ventilation: Natural in weaning, growing, and finishing; artificial only in farrowing.

Lighting: 12h natural + 12h artificial

Outdoor access: No

Feeding: Dry feed ad libitum on straw; liquid feed from long troughs on slatted floors

Diet: Fully commercial

Feeding capacity: 12.5–20% of pigs can eat at once

Water: Nipple drinkers, 1 per 10 pigs - Management Practices

Piglets are grouped by farrowing band to ensure same age and origin. Pens are separated by bars allowing interaction.

Health monitoring: Daily by farmer; weekly (fattening) and biweekly (weaning) by vet or advisor.

Tail biting monitoring: Daily by farmer; biannual vet reports.

Tail biting intervention: Injured pigs are moved to infirmary and treated. Biters are isolated with enrichment material.

Other: 100% of pigs have intact tails and no tooth clipping. - Economic Analysis

– 0% mortality due to tail biting

– 0.5% condemnations at slaughter due to bitten tails

Additional costs stem from increased space allowance and straw use. However, straw reduces infrastructure costs by eliminating the need for slatted floors, forced ventilation, and slurry systems. - Environmental Analysis

Straw manure is either sent to biogas plants or stored on concrete slabs before field application. Slurry is stored in pits on the farm. - Replicable Benefits and Relevance for Other EU Countries

Avoiding tail docking is feasible and beneficial. The farm has practiced this for over 5 years. Benefits include improved animal welfare and greater social acceptability. The Fumagalli Group exports 60% of its products, 25% to the UK, and holds certifications for animal welfare and responsible antibiotic use. All sites are rated ‘gold’ except those with slatted flooring.